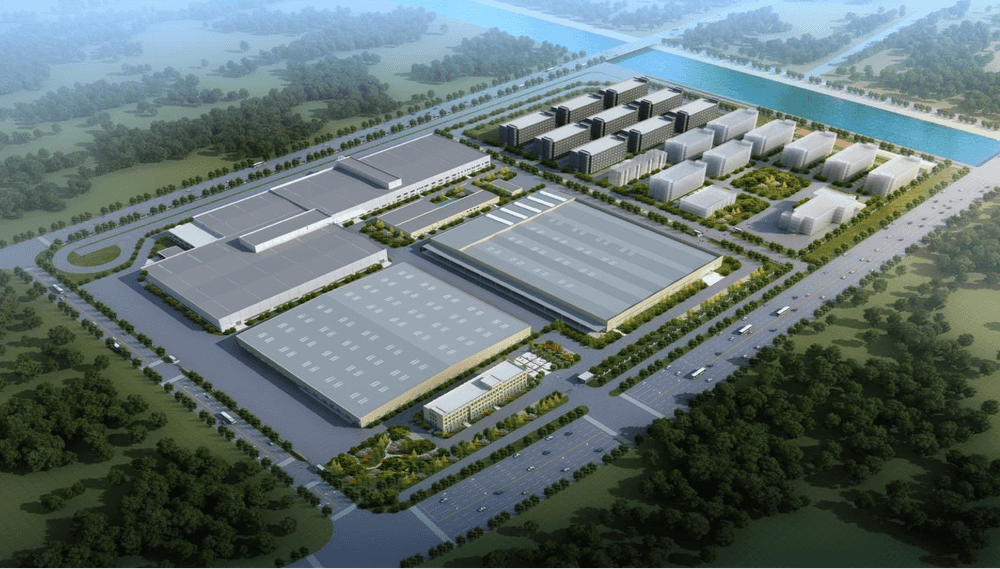

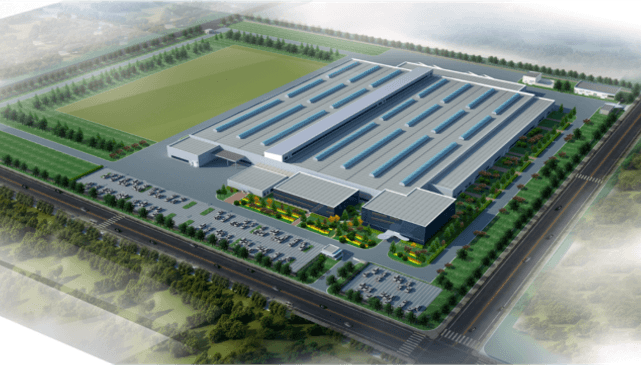

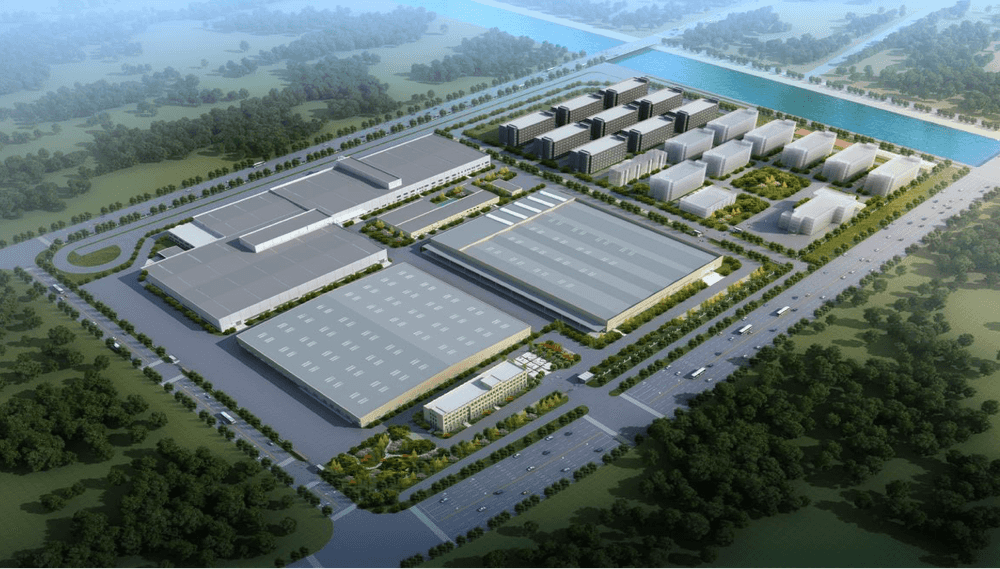

Aurobay Plants

The Aurobay Holding factories lead the way in innovation, high-technology, and efficiency. Our production lines and assembly areas utilize energy-saving technologies, and we are continuously working to further lower the environmental impact from our factories. We seek to meet or surpass all relevant environmental legislation, and our suppliers are expected to follow the same high environmental standards. Aurobay has strict environmental controls. To prevent incidents, we have emergency response plans that are supported by regular data collection and established issue-reporting channels.

Environmental initiatives at our factories

- The Skövde plant is powered solely by renewable energy sources.

- To promote biodiversity, meadow surfaces have been planted to host pollinating species.

- Production waste is sorted and four different by-products are sold to other industries.

- Plastic and wooden pallets have been replaced with recycled packaging material to both reduce waste and lower the environmental footprint.

- Waste aluminum is collected and sent to our aluminum supplier to be reused in our products, creating closed loop resource flows.

- De-noising technologies reduce noise pollution in the local environment.

- Heat is reused from our compressors, cooling systems and ventilation, making Skövde self-sustainable down to 5°C.

- The Zhangjiakou factory is powered by 100% renewable electricity.

- At the Zhangjiakou plant, residue heat generated from oil mist filters, compressor and air handling units are collected to heat up water at the factory, thus saving energy